Summary

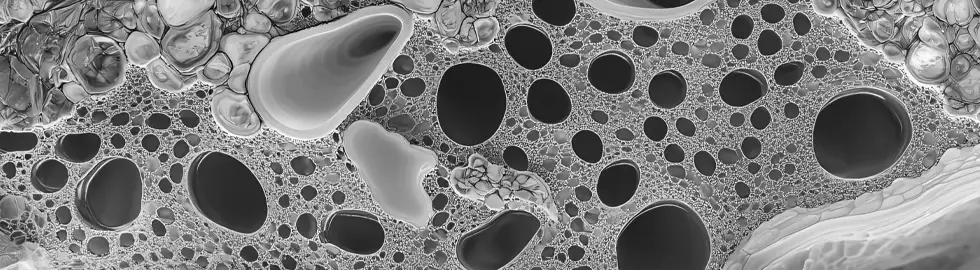

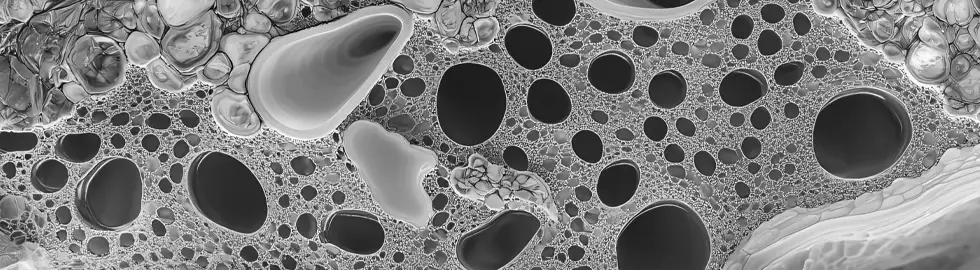

The development and quality control of rigid PVC formulations require precise material characterization techniques to ensure consistent product performance and manufacturing efficiency. This webinar will explore the expansion of vinyl material characterization capabilities through the use of advanced testing methods, specifically focusing on a rigid PVC building product formulation.

A key aspect of this presentation will focus on the integration of various characterization tools, including a Torque Rheometer equipped with a Mixer Measuring Head to monitor the material's viscosity during processing. The Fusion Curve, measured in accordance with ASTM D2538, provides critical insights into the formulation's processing window, indicating the material's ability to undergo fusion under controlled conditions. Additionally, the presentation will demonstrate the utilization of the Slot Capillary Extrusion Die, a method aligned with ASTM D5422, to assess the material's flow behavior and rheological properties.

Viscosity measurements collected throughout the process were correlated with the formulation's performance during extrusion, highlighting the relationship between processing parameters and final product characteristics. Furthermore, color measurements were conducted to evaluate the impact of material formulation on visual properties, which is crucial for product consistency in the building materials industry. By combining these methodologies, this webinar will demonstrate how an enhanced approach to formulation development and quality control can lead to improved processability and product consistency in rigid PVC-based building products, paving the way for future innovations in vinyl material science.

Show more Show Less

Agenda

Who Should Attend?

This event is ideal for professionals in the development, manufacturing, and quality control of rigid PVC formulations and building products. It will benefit materials scientists, product developers, process engineers, and quality assurance specialists seeking to enhance their understanding of advanced characterization techniques like viscosity analysis, fusion curve assessment, and rheological property evaluation. Additionally, R&D researchers and industry consultants focused on improving vinyl material formulations and processability will find valuable insights, making it a must-attend for those aiming to optimize product performance and consistency in the building materials sector.

Why Should You Attend?

Attendees will gain valuable insights into advanced material characterization techniques that can significantly enhance the development, processability, and quality control of rigid PVC formulations. This event will demonstrate how tools like Torque Rheometers, Fusion Curves, and Slot Capillary Extrusion Dies, aligned with ASTM standards, can improve formulation precision and product consistency. By exploring the correlation between processing parameters, rheological behavior, and final product performance, participants will learn how to optimize manufacturing efficiency while ensuring high-quality outcomes. This knowledge is essential for driving innovation and maintaining a competitive edge in the building materials industry.

Registration Information

Register Now

Presenters

Christoph Pielen

Lead Scientist

Anton Paar USA

Christoph Pielen studied Mechanical Engineering at the RWTH Aachen University in Germany. He spent over a decade with Brabender in both Germany and the United States, most recently serving as President of Brabender CWB. He joined Anton Paar as Lead Scientist for Texture and Extrusion.

Scott Martin

Market Development Manager

Anton Paar USA

Scott Martin studied Polymer Engineering at Stevens Institute of Technology in Hoboken, NJ, and has since dedicated his career to supporting customers with polymer application needs. He is a long time member of the Society of Plastics Engineers, and joined Anton Paar USA in 2024 as a Market Development Manager specializing in polymer characterization solutions.

Questions? Contact:

For questions, contact Iván D. López .