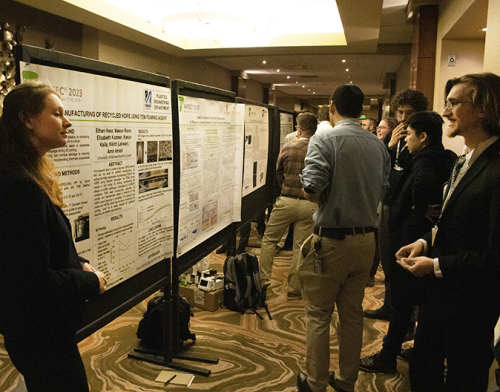

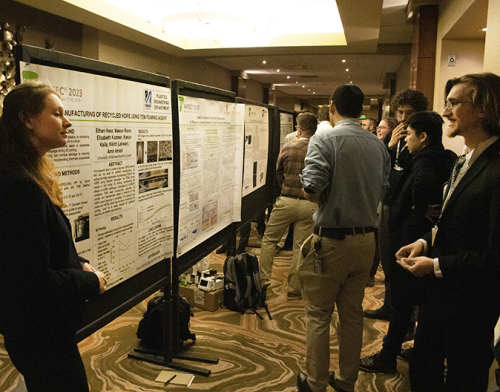

One casualty of the pandemic was the cancellation of an ANTEC® mainstay: the student poster competition, an effective way for college and university students to showcase their research and begin establishing networking connections with industry experts.

At ANTEC® 2023, plans were to announce three winners in the restored competition, which took place March 28. The 50 or so posters displayed and the high quality of research they represented led organizers instead to announce four honorable mentions as well.

At ANTEC® 2023, plans were to announce three winners in the restored competition, which took place March 28. The 50 or so posters displayed and the high quality of research they represented led organizers instead to announce four honorable mentions as well.

First place went to Hannah Lacy, a graduate student pursuing a Ph.D. in materials science at the University of Alabama, Birmingham. She and her colleagues did research at the Technical University of Liberec in the Czech Republic on the method of alternating field electrospinning. Her work focused primarily on high-throughput fabrication of blended natural and synthetic biopolymeric nanofibrous scaffolds. After she graduates in April, she will explore research opportunities in a national laboratory or an industry position.

In second place was Badal Lodaya, a Ph.D. candidate in the chemical engineering department of Michigan State University. His research involves the design and engineering of value-added products from polylactic acid for industrial applications. He works with Dr. Ramani Narayan of the Biobased Materials Research Group.

Amin Jamei Oskouei took third place. A PhD candidate in macromolecular science and engineering at Case Western Reserve University, he presented research on recycling thermoset polymers and on structure-properties relationships. Additionally, he has experience in rheology, composites and nanocomposites from previous studies.

One of the four students who won honorable mentions for their posters was Jake Kelly-Walley. Sponsored by his employer Matrix Polymers, he is working toward a Ph.D. at Queens University, Belfast, in the School of Mechanical and Aerospace Engineering/Polymer Processing Research Center. His research is focused on a more sustainable future for rotational molding materials, through greater use of recyclate, compatibilization, fillers/fibers and polyolefin blends.

At ANTEC® 2023, plans were to announce three winners in the restored competition, which took place March 28. The 50 or so posters displayed and the high quality of research they represented led organizers instead to announce four honorable mentions as well.

At ANTEC® 2023, plans were to announce three winners in the restored competition, which took place March 28. The 50 or so posters displayed and the high quality of research they represented led organizers instead to announce four honorable mentions as well.

.jpg)

.jpg)

.jpg)

.jpg)