Antiblocks (AB) and Polymer Processing Additives (PPA) are just two components of the additive package that ensure performance in LLDPE blown film applications. While ABs are critical to the quality manufacturing of these films, they are known to interfere with the performance of the PPAs. Past studies assessed the additional PPA required to offset these impacts, but as newer, high-performing PPAs and ABs entered the marketplace, it became necessary to revisit the study for a more complete view of possible interactions.

Measuring PPA and AB interactions

In 2014, the 3M Advanced Materials Division quantified the influence of several ABs on PPAs in LLDPE blown films. The resulting paper, “Fluoropolymer Polymer Processing Additive – Antiblock Interactions” by Madhusudan Chari, PhD, 3M, Advanced Materials Division, was presented by the author at the 2014 SPE International Polyolefin Conference.

The materials used in the study included:

- Three 3M™ Dynamar™ PPA formulations recommended for blown film extrusion;

- Ten ABs received directly from the manufacturer which included uncoated, specialty and coated talcs; nepheline syenite and synthetic silica. These minerals were compounded by 3M for this study;

- Two commercially available AB masterbatches, one with an AB concentration of 60% talc, and one with 15 % natural silica in an unspecified PE resin system.

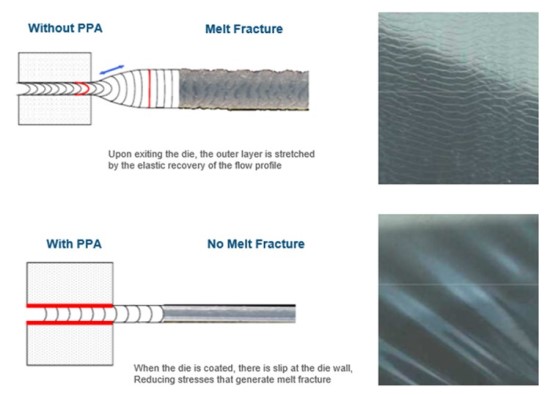

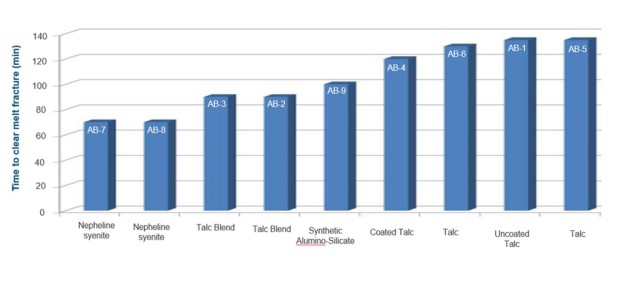

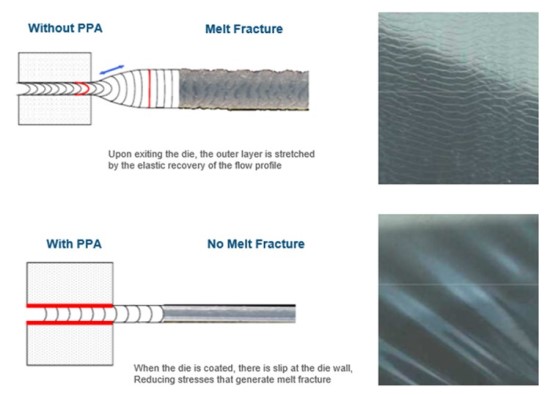

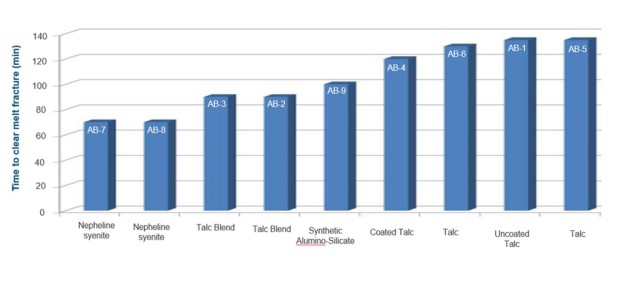

With a focus on blown film production, researchers chose melt fracture elimination to measure PPA performance. By plotting the remaining percent of melt fracture vs. time, they were able to compare how different ABs affected PPA usage and performance. Longer time-to-clear-melt-fracture (TTCMF) implied more interference of the AB with the PPA; therefore, the shorter TTCMF meant less interference of the AB with the PPA.

Melt Fracture effects on polymer

Source: Fluoropolymer PPA Anti-blocking Interactions, Madhusudan Chari / 3M Advanced Materials Division

Study Outcomes

In reviewing the data on the ten ABs compounded by 3M, nepheline syenite was found to have the shortest TTCMF and the least interference with the PPAs. In terms of AB interaction affecting PPA performance (measured by time/amount to clear melt fracture) the following conclusions were made:

- The uncoated talcs affected PPA performance the most by doubling the TTCMF and required the most PPA.

- The coated talcs took 55 mins longer TTCMF than the nepheline syenite ABs.

- The synthetic silica ABs took 35 mins longer TTCMF than the nepheline syenite ABs.

- The specialty grades talc took 30 mins longer TTCMF than the nepheline syenite ABs.

- The nepheline syenite AB affected PPA performance the least and had the fastest TTCMF of all ABs evaluated/compounded by 3M.

Time-to-clear-melt-fracture graph

Based on this study, one can conclude that nepheline syenite will have the least interference with other polymer additives such as slip, antioxidants and UV protection. Manufacturers of LLDPE blown films can evaluate their current additive package to determine if, by changing their current AB, they can potentially reduce the quantity of other, more expensive additives and reduce overall costs.

Download full 3M study here.

Contact Covia:

www.coviacorp.com/markets/polymers

3 Summit Park Drive, Suite 700

Independence, OH 44131

polymers@coviacorp.com

.jpg)

.jpg)

.jpg)

.jpg)