Are you struggling to achieve weight savings in your designs without compromising performance?

Do you face challenges in optimizing part design for lightweighting while maintaining structural integrity?

Is it difficult to find a reliable way to reduce material density in your injection molding processes?

Are you unsure about how to integrate foam injection molding techniques into your designs to improve efficiency and reduce mass?

Do you lack the knowledge of how core-back foam injection molding can offer unique design flexibility for your applications?

If these questions resonate with you, this course was designed to help you solve them.

Everyday Problems You’ll Address:

How can I use foam injection molding to significantly reduce weight without sacrificing performance?

What makes core-back foam injection molding different from traditional injection molding—and when should I use it?

How do I design parts that take advantage of expansion behavior while maintaining dimensional control and mechanical strength?

What role does material data play in designing for foam injection?

Can I trust this method for demanding applications in automotive or technical components?

What You’ll Learn:

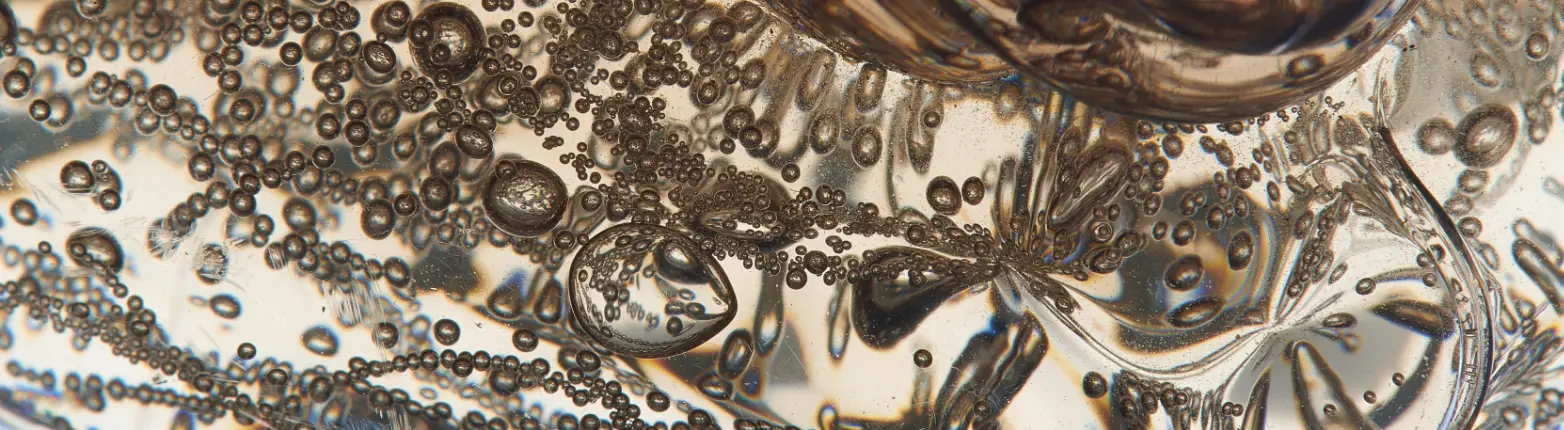

The core mechanics of core-back foam injection molding and how it enables lightweighting by strategically controlling part geometry and density.

Design guidelines and best practices tailored to this process, using material engineering data to inform smart decisions.

A real-world case study showing how core-back design can achieve up to 20% weight savings without compromising performance.

Practical steps to integrate this technique into your development process, from concept to manufacturing.

How to unlock the full potential of foam molding to meet performance, cost, and sustainability goals.

Why This Course Matters:

As lightweighting becomes a key goal across industries, traditional solutions often fall short. Material substitution alone can only go so far—smarter, more flexible design strategies are needed.

This course gives you a solid foundation in a specialized technique with powerful potential. You'll walk away ready to:

Design lighter, high-performance parts with confidence.

Apply a proven process to reduce mass while meeting technical requirements.

Bring innovation into your projects with a practical, engineering-first approach.

If you're ready to elevate your design strategy and embrace lightweighting through advanced molding, this course is for you.